Repiping

What is Repiping?

What is Repiping?

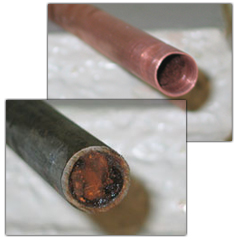

Re-piping is a process of replacing the supply pipes in a dwelling or business. It is not a temporary fix or a replacement of short sections of pipe, but a complete replacement of your supply plumbing system. There are several reasons you may need to repipe your home or business. Corrosion of pipes may cause low water pressure, rusty colored water, reduced water flow, or leaks. If you are going to remodel it is a good time to repipe before you paint or finish your walls. It is important to understand the scope of the project before work is started. If you notice an isolated leak or a small portion of your existing piping leaking, or valves that are corroded or cracked, it is quite possibly an indication of a larger problem.

Repiping is a process of installing a new copper repipe system. This process usually includes removing old readily accessible pipe and then installing the new plumbing system. Included in the process is the installation of new USA type "L" hard copper, properly strapped and secured, install kwik 1/4 turn ball type water stops, install new stainless steel water supply lines. After the new piping system is installed the water is turned back on, the system is pressure tested and then flushed out. The repiping process takes 1-3 days to install the new piping system. After the actual plumbing replacement, there will be some required wall patching.

A professional site inspection is critical to a successful repiping process. Standard repiping projects include installation of all new hot and cold domestic water piping from the water source to all existing faucets and fixtures. Unless specifically included in the proposal, drain replacement and fixtures are not included.

There are various materials used in re-piping, in water supply re-piping some of the materials are metal and perhaps some plastic pipes. The metal pipes are galvanized steel or iron, brass, and copper. The plastic pipes are Poly Vinyl Chloride PVC, Chlorine Poly Vinyl Chloride CPVC, Poly Ethylene PE, Polybutylene PB, and Kitec. Most of these plastic pipe systems will end in lawsuits. Part of the problem is with the fittings that are often cheaply made with little quality control by a verity of overseas companies. Plastic pipes also have questionable joining methods. Plastic pipes are glued, crimped, and banded. When plastic pipes blow a joint they blow apart and result in water damage. Plastics become brittle with age and heat. There are also issues about the molecular structure of plastics and the resins from which they are made.

In rare instances a CPVC repipe maybe recommended where the water PH levels are a problem.

There are various materials used in re-piping, in water supply re-piping some of the materials are metal and perhaps some plastic pipes. The metal pipes are galvanized steel or iron, brass, and copper. The plastic pipes are Poly Vinyl Chloride PVC, Chlorine Poly Vinyl Chloride CPVC, Poly Ethylene PE, Polybutylene PB, and Kitec. Most of these plastic pipe systems will end in lawsuits. Part of the problem is with the fittings that are often cheaply made with little quality control by a verity of overseas companies. Plastic pipes also have questionable joining methods. Plastic pipes are glued, crimped, and banded. When plastic pipes blow a joint they blow apart and result in water damage. Plastics become brittle with age and heat. There are also issues about the molecular structure of plastics and the resins from which they are made.

In rare instances a CPVC repipe maybe recommended where the water PH levels are a problem.

A new trend in re-piping is sand blasting the inside of worn thin pipe and the painting the inside of the worn pipe with epoxy paint. Sometimes during the sandblasting the sandblasting will wear thin and blow through the wall of joints and pipes. Some of those thin spots leak right away and sometimes those leaks come days or weeks later. Leaking pipes that are epoxy-coated end up needing to be properly re-piped by installing a CDA copper re-pipe.

Copper or Plastic Piping?

The problems with plastic piping is a growing problem. Plastic manufacturers are actively spending money to lobby for legalization of plastic piping.

The problems with plastic piping is a growing problem. Plastic manufacturers are actively spending money to lobby for legalization of plastic piping.

For PEX pipe click here.

For Plastic pipe click here.

For PVC Repiping click here.

For House repiping click here.

For Kitec repiping click here.

Copper is the proven choice. However, copper is becoming more expensive. Copper that is used in re-piping should be hard USA manufactured copper, properly installed and protected. Avoid re-piping with soft copper. When the soil is "Hot" protect the copper pipe with plastic sleeving. It is not recommended that copper be buried under concrete slabs. Copper pipe that is buried should be buried in sand or clean soil free of rocks and boulders that can damage the copper pipe when compacted. Also anywhere pipes make penetrations through concrete it should be wrapped or protected and given adequate clearances for movement and settling.

Properly installed USA CDA copper has a 50 year warranty.

In order to help homeowners, potential homeowners, and consumers make educated decisions when it comes to plumbing, the CDA has developed a 12-point Plumbing Test. Not surprisingly, copper is the only plumbing material that can answer "yes" to each of the following questions. How does your plumbing material match up?

The CDA 12-Point Plumbing Test:

1. Does your plumbing material have a long-term, proven performance record?

2. Is it permeable; can it block contaminants from penetrating its walls?

3. Can the joints withstand rapid pressure and temperature changes?

4. Will it perform well in all weather, and is easily thawed, if necessary?

5. Does it resist punctures and abrasions and not become brittle with age?

6. Does it inhibit the breeding of harmful germs?

7. Will it not burn, or give off smoke or toxic fumes, when exposed to fire?

8. Will it withstand the weather and the sun's ultraviolet rays in outdoor applications?

9. Is it maintenance-free and has a low lifetime cost of ownership?

10. Will it add to your home's resale value?

11. Does it have nationwide approval of building inspectors and engineers?

12. Does it have inherent quality and value, or offer 'false economy' like some competing materials?

Plumbing Codes

This is to be used as a general checklist; it is not inclusive of all code requirements and inspection criteria:

Job card to be on site, construction placard displayed and filled in and displayed in a visible location.

New copper water service shall be at least 12” below the average local frost depth, the minimum cover shall be 12” below finished grade. CPC sec.609.1 Copper water lines to be placed under test to determine whether water pressure exceeds 80 pounds.

Pressure regulator is required when water pressure exceeds 80 pounds. CPC sec. 608.2. Burred ends of all pope and tubing shall be reamed to the full bored of the pipe or tube and all chips shall be removed. CPC sec. 310.3 No building supply pipe shall be less than 3/4 inch in diameter. CPC sec. 610.8 Copper tubing for water piping shall have a weight of not less than Type L. CPC sec. 604.2

A full valve controlling all outlets shall be installed on the side of each water meter and on each unmetered water supply and all valves shall be accessible at all times. CPC sec. 605.2 In multi-dwelling units, one (1) or more shutoff valves shall be provided in each dwelling unit so that the water supply to any plumbing fixture or group of fixtures in that dwelling unit can be shut off without stopping water supply to fixtures in other dwelling units. CPC sec. 605.3

Upon completion of the entire repipe system, the hot and cold water supply system shall be tested and proved tight under a water pressure not less than the working pressure under which it is to be used. A (50) pound psi air pressure may be substituted for the water test. In either method of test the piping shall withstand the test without leaking for a period of not less than fifteen minutes. CPC sec. 609.4 Copper piping run through framing members to within (1) inch of the exposed framing shall be protected by steel nail plates not less than 18 gauge. CPC sec. 313.10 Penetration of fire-resistive walls shall comply with CPC sec.709.1 or CBC sec. 709.6.3. Also see exception 1 & 2 Penetration of fire-resistive horizontal assemblies shall be enclosed in fire-resistive shaft enclosures in accordance with CBC sec. 711.1 or shall comply with CBC sec. 710.2.2 or CBC sec. 710.3. And see exceptions 1,2 & 3 Revised 12/02/05 Page 1 of 2 City of Santa Monica Building and Safety Division Copper Water Line Repipe Checklist All pipes subject to undue corrosion, erosion or mechanical damage shall be protected in an approved manner. CPC sec. 313.5

Any structural member weakened or impaired by cutting, notching, or otherwise shall be reinforced, repaired or replaced so as to be left in a structural condition in accordance with the requirements of the California Building Code. In or on building where opening have been made in walls floors, or ceiling for the passage of pipes, they shall be closed and protected by the installation of approval metal collars securely fastened to the adjoining structure.

Test Gauge: Required pressure tests exceeding ten (10) pounds but less than one hundred (100) psi shall be performed with gauges increments of (1) psi incrementation or less, CPC sec. 319.2. The test gauge shall have a pressure range not greater than twice the pressure applied, CPC sec. 319.4 Hangers and Supports: Suspended piping shall be supported at intervals not to exceed those shown in Table 3-2 of the CPC sec. 314.1. Hangers and anchors shall be of sufficient strength to support the weight of the pipe and its contents, CPC sec. 314.4.

Hot and cold piping insulated within 5’ of water heater, (energy, Cal 123a) Insulate all hot recirculation pipes from Boiler/Water heater, (energy) Potable Water Outlet with Hose Attachment (hole bibb): Shall be protected by non-removable hose bibb type back flow preventer. ( Anti-siphon device on hose bibb), CPC sec. 603.4.7 Addition, alteration or repair to Group R occupancies: When the valuation of an alteration, repair to a Group R exceeds $1000 and a permit is required, smoke detectors shall be installed in accordance, with CBC sections 310.9.1.3, 310.9.1.4, and 310.9.1.5. (CBC sec. 310.9.1.2.)

Any building permit or inspection carried out by the Building and Safety division all water heaters shall be braced in conformance with the minimum standard established by the Division of the State Architect or the California Building Code. SMMC 8.08.130 Check electric service bond & bond all metal piping All hot water to be insulated as per SMMC ;

Free Plumbing & Repiping Estimate for Commercial and Residential Jobs

Contact Henrik Plumbing today by phone or email:

Phone: 888-443-6745 | 323-258-5858

Email: info@henrikplumbing.com